Leading the Skies in Helicopter Innovation

Pioneering safe, reliable, and ultra-high-performance helicopters for government, commercial and private sectors

Safety

RETAVIA delivers unmatched safety through decades of aviation expertise, advanced engineering, and next-generation materials that ensure every helicopter exceeds global reliability standards.

Performance

RETAVIA’s helicopters achieve exceptional performance through expert engineering, efficient aerodynamics, and cutting-edge manufacturing that maximize capability, power, and operational excellence.

Innovation

Driven by patented technology and digital precision, RETAVIA pushes the boundaries of vertical flight with breakthrough innovations in modern rotorcraft design.

Innovating Aviation with Expertise

RETAVIA, Our technical team members have over 3 to 5 decades of expertise each in aviation technology and helicopter manufacturing, we design and build helicopters that set new standards for safety, performance, and innovation. Our commitment to excellence and cutting-edge engineering ensures that every aircraft we create meets the highest standards of quality and reliability.

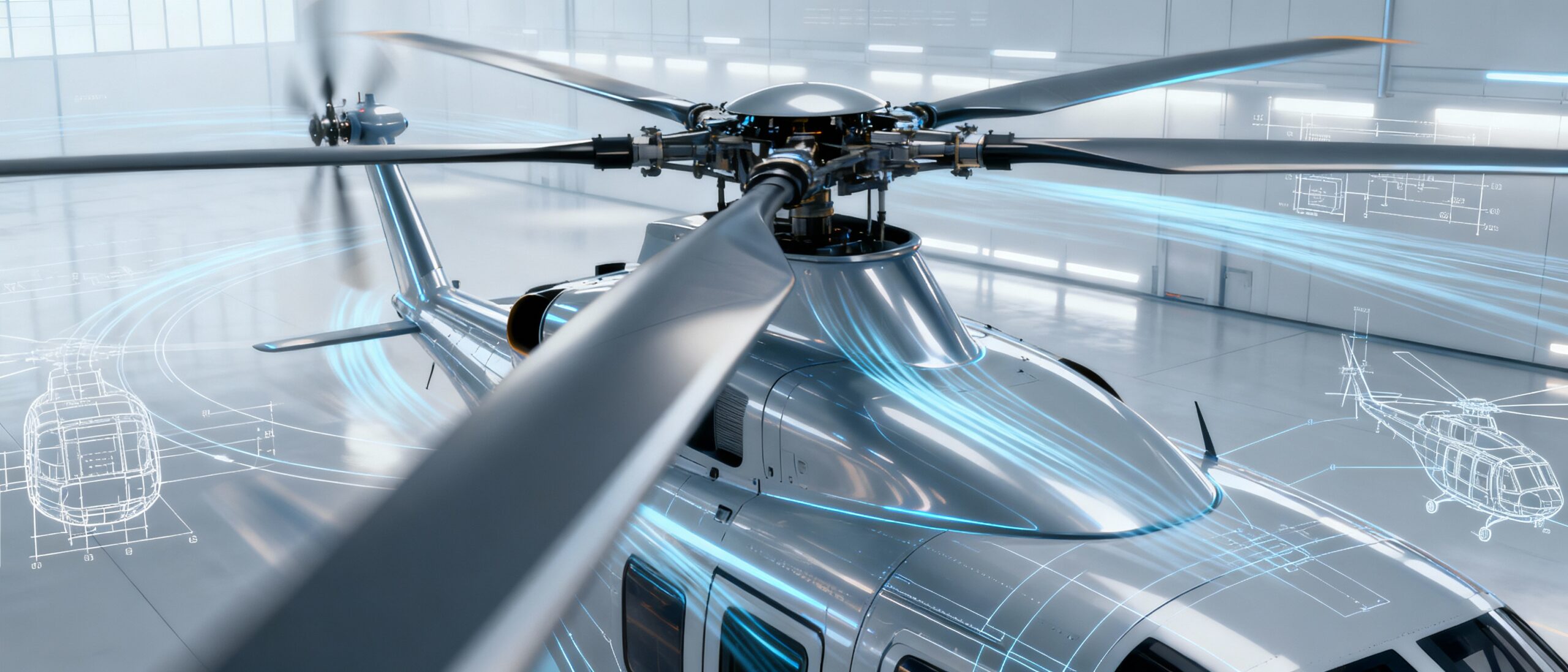

The Future of Vertical Flight

Welcome to RETAVIA, where advanced aerospace engineering and patented technology meet modern innovation to create the safest, most efficient, high-performance rotorcraft. We redefine vertical lift and deliver the future of flight today.

Technology & Innovation: Patented Excellence

Our competitive edge is built on proprietary knowledge and technology, protected by a growing portfolio of global patents. We invest heavily in R&D to maintain our position at the forefront of the industry.

Advanced Systems and IP

Cutting-edge systems redefining efficiency, strength, and zero-defect helicopter manufacturing.

Patented Rotor & Blade Systems

Featuring our proprietary designs, significantly reduce drag, increase fuel efficiency, and minimize acoustic signature, setting new benchmarks for performance.

Additive Manufacturing

We integrate specialized, high-stress components produced via selective laser sintering (SLS) and electron beam melting (EBM), allowing for complex geometries and superior strength-to-weight ratios that are impossible with traditional methods.

Digital Airframe Integration

Our manufacturing process relies on a "Digital Twin"—a virtual replica of the aircraft—enabling real-time stress testing, predictive maintenance, and flawless component integration, ensuring every helicopter is built to zero-defect standards.

Next-Generation Composites

Utilizing patented technologies, we produce airframes and structural elements that are lighter and vastly more durable than traditional aluminum or titanium alloys.

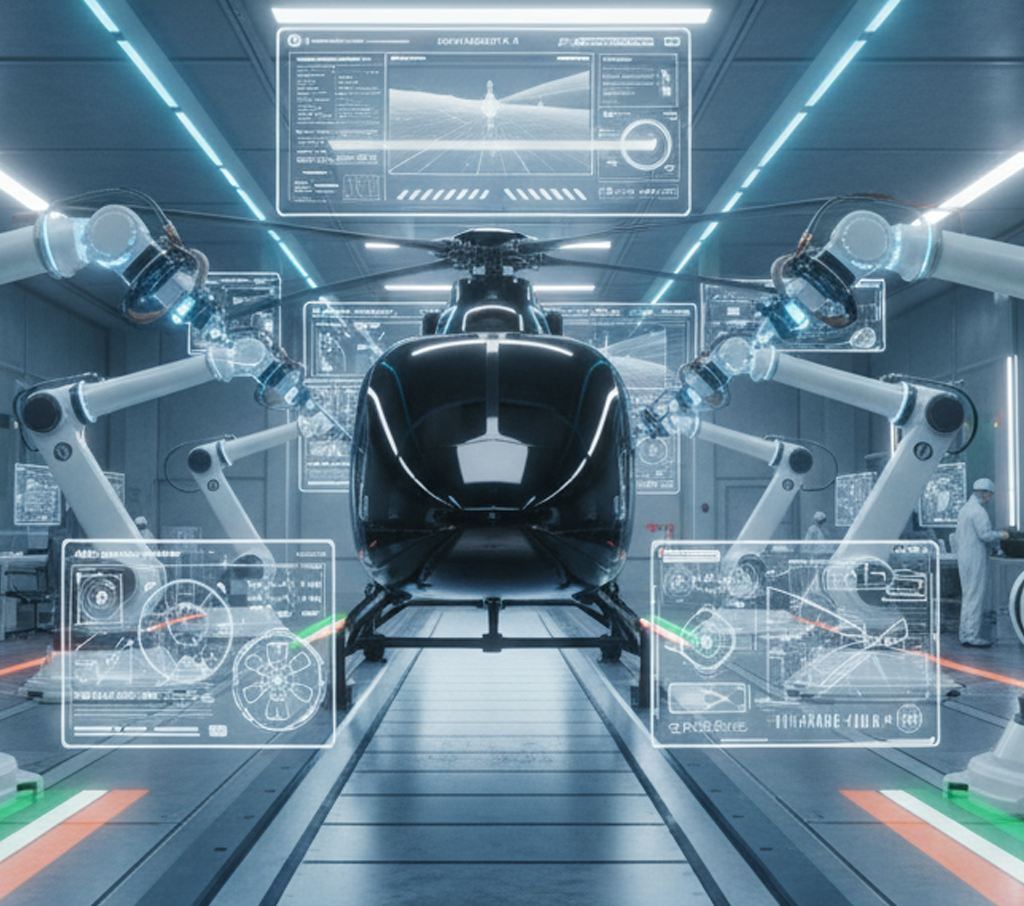

Manufacturing Precision at Scale

Our factory stands as a true Industry 4.0 benchmark, integrating advanced digital systems, automation, and robotics to deliver unmatched precision, speed, and efficiency in aerospace manufacturing.

As part of the Government of India’s Made in India initiative, the helicopter models and variants of the Retavia AAD555will be indigenized in a phased manner. This mission aligns with the vision and guidance of the Hon’ble Prime Minister of India, Shri Narendra Damodardas Modi ji, whom we at Retavia regard as a key architect of modern India’s technological transformation.

At Retavia, we believe that world-class production standards—in quality, safety, and reliability—are non-negotiable. Our facility complies with the most stringent global aviation regulations, strengthened by the assurance of our patented technologies and certified processes.

Proprietary Testing Excellence:

Every aircraft undergoes Retavia’s exclusive Flight Acceptance Program, a rigorous evaluation protocol combining extensive ground assessments and precision flight trials. These tests are uniquely structured to validate and verify the superior performance of our patented systems and engineering innovations.